High Pressure Processing extends the shelf life of food products

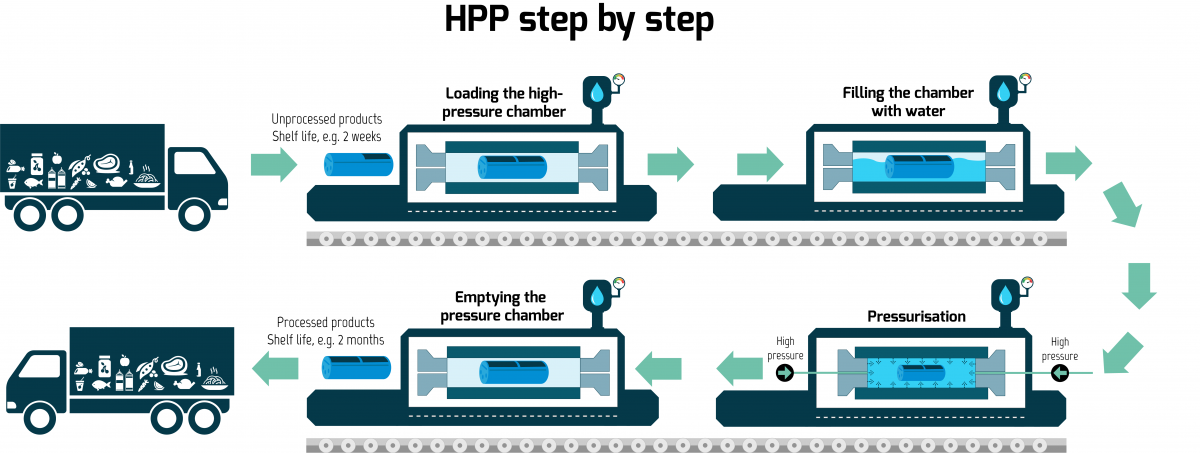

High Pressure Processing (HPP) is a method of processing food in its sales packaging. As a result, the shelf life of food products is extended multiple times.

High Pressure Processing is suitable for products with a high water content that are packed in watertight, flexible packaging. The products are exposed to pressure of about 6000 bar for 3-6 minutes. The process denaturises pathogens such as listeria, salmonella and norovirus as well as many yeasts and moulds. The properties of the products remain unaltered.

The process chamber has a holding capacity of 350 litres and a production capacity of 1500 kg per hour. In practice, the daily capacity is about one lorryload.

Watch video:

Applications include:

- Ready-made meals

- Packaged meat and fish products

- Prepared salads

- Vegetables, fruit, berries

- Dairy products

- Pet food

Benefits for producers, retailers and consumers:

- Food safety is improved

- The need for preservatives and additives is reduced

- Shelf life is extended

- Food waste is reduced

- Export costs are reduced (products do not need to be frozen)

- It is easier to plan for seasons

- Replaces pasteurisation and heat treatment

- Products’ structure, nutritional values and taste remain unchanged

- A simple method: only water and electricity are used

Adopt the new method

We will open Finland’s first industrial-scale HPP plant with the required logistics centre in Suonenjoki in August 2018. Please get in touch so we can discuss how to best use High Pressure Processing in your business!

Toripiha Oy

Juho Kylmälä

Managing Director

Tel. 010 425 2703

juho.kylmala(at)toripiha.fi